|

|

||||||||||||||

|

|

||||||||||||||

|

|

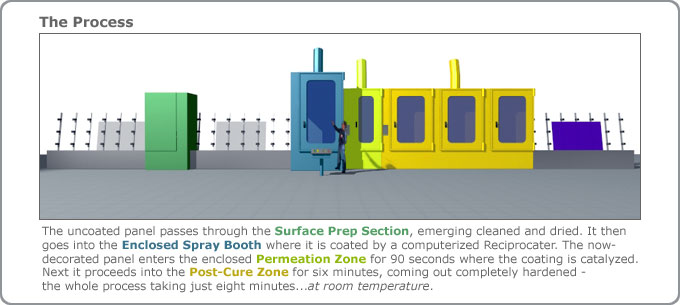

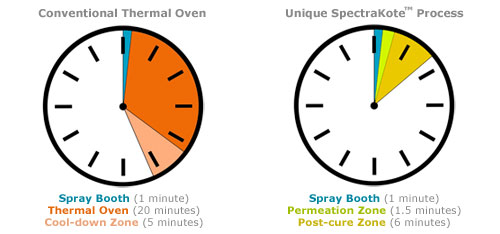

As with most manufacturing processes, time is of the essence when applying protective and/or decorative finishes. Having to wait 24 hours between coats of paint is a significant liability in terms of labor costs, the extra risk of inclusions and fiber lift, the cost of providing space for air drying and slower delivery times to customers. Speeding things up with a thermal oven also has its downsides in the form of capital outlay and running costs. (If you've invested in an oven, do you have any idea how much money you shell out every month for energy?) SpectraTechnology solution - The article is coated with a specifically formulated 'paint' before moving into a recirculating (invisible) catalyst atmosphere at room temperature (⊇15°C). Here the wet coating absorbs molecules of catalyst and curing begins. Instead of 24 hours, SpectraKote™ takes just eight minutes to cure. Totally. No matter how high the specific gravity of the article. Eight minutes is also less than a third of the time it takes for paint to dry in a thermal oven. And there are no excessive energy bills to worry about either. (For a more scientific description of what happens from go to whoa along our super-efficient production line, please check out the Basic Theory behind SpectraTechnology.)

Some additonal benefits - For most manufacturers big savings in production time and operating costs are two pretty compelling reasons for seriously considering new technology. But SpectraTechnology offers even more advantages. For instance, reduced curing time means less opportunity for inclusions to mar finishes and solvent penetration to cause fiber lift. You can use any color then change to another simply by pushing a button to flush all your hoses and nozzles. You can also offer much quicker delivery times than your competition. And find another use for all the space you've be using for air drying.

More info - If you would like more information about how SpectraTechnology can help your operation run more efficiently, just click Contact Us to e-mail your questions. |